Welding Cobot Solutions

Increase your productivity through advanced technology

Discover SmoothTool — a compact, user-friendly software solution designed to streamline welding and manufacturing workflows without the complexity or high cost of traditional robotics. Whether you’re looking to boost productivity, reduce manual labor, or get started with automation, now’s the perfect time to invest!

Available exclusively through DCISIV Technologies — Premium Smooth Robotics Partner, certified systems integrator for Universal Robots, and your trusted Queensland distributor.

Cobot Welding Package by DCISIV

- Universal Robots UR10e Cobot with Pendant Bumper, Screen Protector, Insulated Robot Mounting Plate and Pendant Stand

- SmoothTool Lifetime License with Flange

- EWM Phoenix 355 Gas Cooled Power Source Package

- 3.15m Gas Cooled Torch with Flange Adapter, Spring Balance, and Cable Holder

- 1500mm x 1500mm Nitrided Weld Table – 100mm, 28 DIA Hole Pattern with 82 Piece Clamp Kit with Trolley

- Air Pulse Solenoid, Stack Light, and External Control Station

- Package Setup and Initial Configuration

- Onsite Commissioning and Training for Key Staff (2 Days FTE)

Key Features of SmoothTool

Our welding automation software is packed with features to enhance your productivity and ensure high-quality welds every time.

3D Visualization

Visualize and touch up your program in 3D

Stitching

Control your stitch weld with custom parameters

Surfacing

Apply hardfacing and cladding easier than ever

Weaving

Add weaving patterns to linear and circular paths

Touch Sense

Locate the position of your piece and adjust the path

Seam Tracking

Auto-adjust the path with through the arc seam tracking

Multipass

Easily create a weld with multiple passes

Offset

Copy and offset in all directions and rotation

External Axis

Add a linear or rotating axis with our external axis support

Angle System

Simply type in the desired work and travel angles

Tacking

Make precise consistent tacks for superior quality

Profile System

Create, save and reuse welding parameters

Case Studies

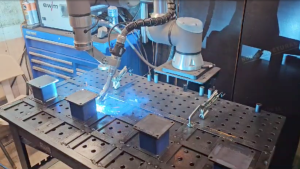

SmoothTool & EWM Phoenix 355 Power Source

Are you ready to unlock unparalleled efficiency and precision in your welding operations?

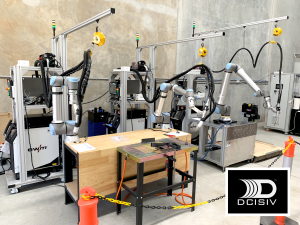

Cobot Welding Cells

Destined for Dalby, Queensland – these three cobot welding cells were comprised of three EWM Titan 400 XQR welding power sources, two Universal Robot UR10e’s and one UR20 with a reach of 1750mm. This was the first UR20 cobot welding application in Australia.

Automate welding processes in your manufacturing operations with a collaborative robot from DCISIV