The Challenge:

Traditionally, welding processes have been time-consuming, labor-intensive, and often prone to human error. Our client in Maryborough, a leading manufacturing company, faced similar challenges in their welding department. They needed a solution that could enhance productivity, improve quality, and reduce dependency on skilled labor.

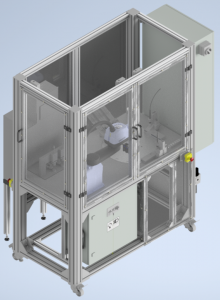

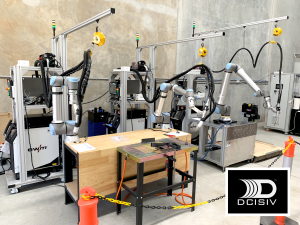

Our Solution:

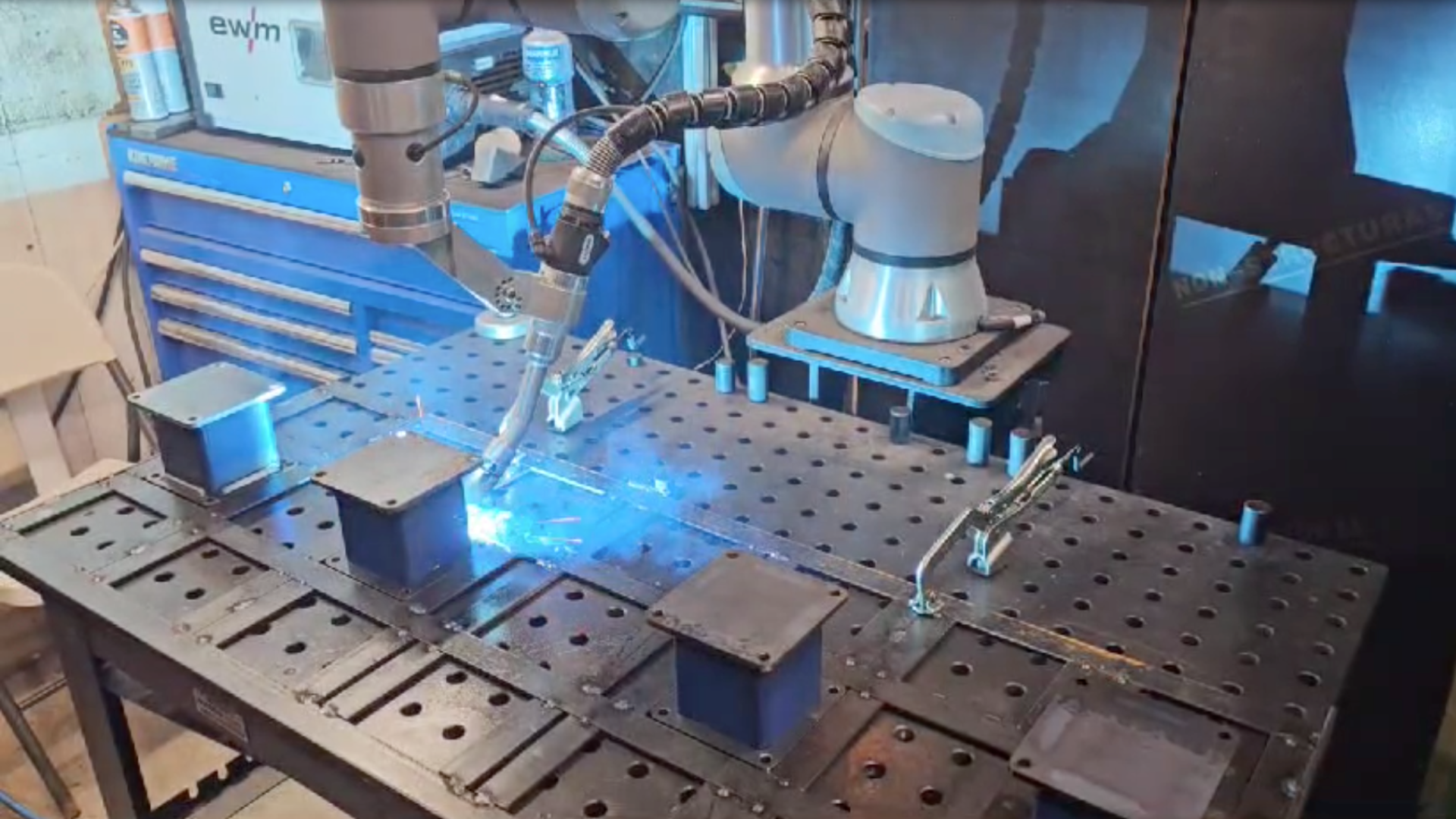

Enter our cobot welding system powered by SmoothTool, meticulously designed to revolutionise the way welding tasks are performed. By integrating collaborative robots into their workflow, our client witnessed a remarkable transformation. With minimal training, a 16-year-old apprentice was empowered to operate our cobot welding system. Armed with just a few simple instructions, the technology was embraced with enthusiasm and confidence. The results? Not only did the apprentice meet the standards of a seasoned tradesperson, but he also completed welding tasks in half the time previously required.

Key Benefits:

Enhanced Efficiency: Reduce production time and meet deadlines with ease.

Exceptional Quality: With precise, repeatable welds, you ensure consistent high-quality results.

Accessible Automation: No extensive training or specialised skills required. Apprentices can operate our cobot system effectively, empowering your workforce like never before.

See it in action:

Why Choose Us?

At DCISIV Technologies, we understand the importance of simplifying complex processes and delivering tangible results. We tailor solutions that resonate with your needs and aspirations. With our cobot welding system, you’re not just investing in technology – you’re investing in a future where efficiency, quality, and innovation reign supreme.

Take the next step:

Ready to transform your welding operations and unlock a new era of productivity? Contact us today to schedule a consultation and discover how our cobot welding solution can elevate your business to new heights.

Unlock the power of automation and experience the future of welding with cobot integration.

“The Cobot welding set up from DCISIV is working very well, the programming is fairly quick once you have the parameters sorted and the repeatability is very good. The quality and consistency are ~80% better than an experienced welder. Production time on some jobs has more than halved, and precise control of the weld size means grinding and post-processing has been massively reduced – and in some circumstances eliminated completely. Once the job is set up and running it can be repeatably produced with unskilled labour, freeing up our experienced Trade based Boilermakers to work on less mundane, repetitive work and utilise their skills on processes that are more complex and interesting.”

- Fabrication company, Maryborough QLD