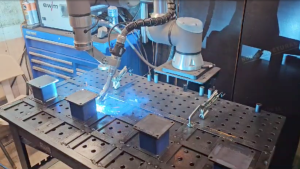

Each cell was fitted with an equipment mounting frame with overhead boom and cable management. The two UR10e cells were fitted with on torch fume extraction and the UR20 cell was fitted with an external cleaning station. The site installation was complete with two 2.4×1.2m welding tables and one 3.0×1.5m welding table.

Three new Smooth Robotics powered cobot welding cells being prepared for Factory Acceptance Testing and delivery in our Toowoomba workshop.

Nation-wide and world-wide skill shortages are not only driving up the cost of labour, but are also placing new constraints on manufacturers and their ability to meet demand and make a profit.

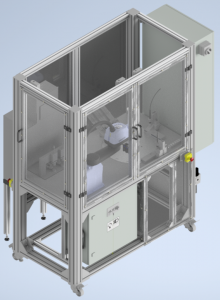

Whether your company has high volume, low mix or low volume, high mix batch production welding requirements – our unique Cobot Welding Package, with SmoothTool, makes it easier than ever before to train your team to utilise robots as a tool within their production workflow.

The global market is moving quickly. Automation is no longer a nice-to-have, it is critical to your competitive advantage.

Inspire your team and increase their productivity by taking away the tedious and dirty aspects to their work.

Contact Us to invest in your company’s future – your team will thank you.