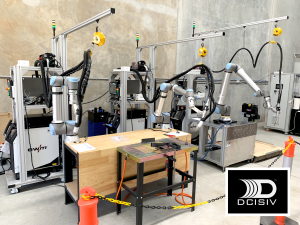

DCISIV Technologies have been helping a Client on their path to automating the assembly of their PolyCell. Several ancillary stations have been designed, prototyped, tested, and revised by DCISIV to eliminate risk, and at the same time work with their budgets.

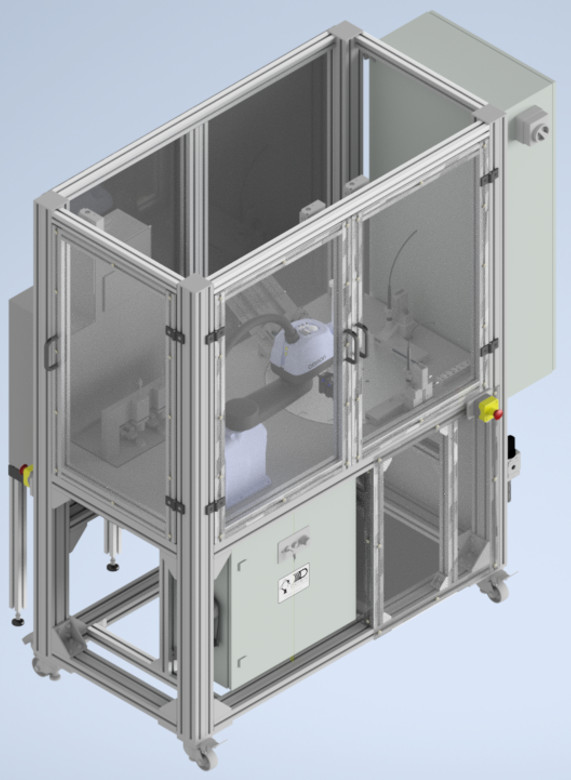

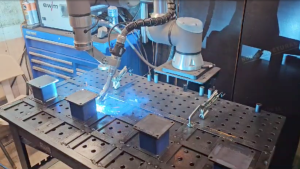

The entire project comprises a modular assembly cell combining frame building, safety guarding, robotics, rotary positioning, and rapidly prototyped ancillary stations to perform automated operations on parts.

The system utilises 3D-printed end use parts, machined components, and off-the-shelf hardware.