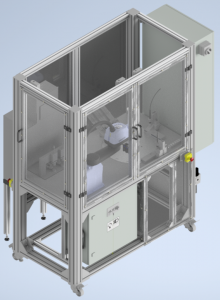

To capture a portion of the Global Market for initiating systems, the Client needed to build a greenfield plant in a foreign country.

Most of the equipment for the plant was built and commissioned in Australia using local expertise.

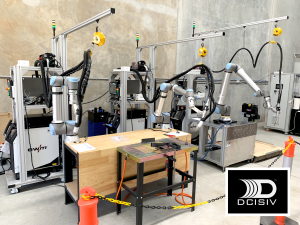

DCISIV Technologies formed part of the project team and worked in close partnership with the Client, Downey Engineering, 5th Dimension Design,

and Toolshop Engineering to organise, assess, build, commission, and ship Initiating Systems Equipment for the site.

The project required strong communication and organisation with multiple vendors to achieve the required outcome.

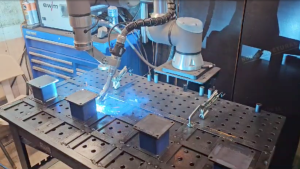

*For illustrative purposes as we have limited access to photos.

The machine shown here was a different project managed internally. Though one of our team members did work on this project as an employee of the client at the time.